Cultivating Fuel on Farms and the Growth of the US Farm Digester Industry

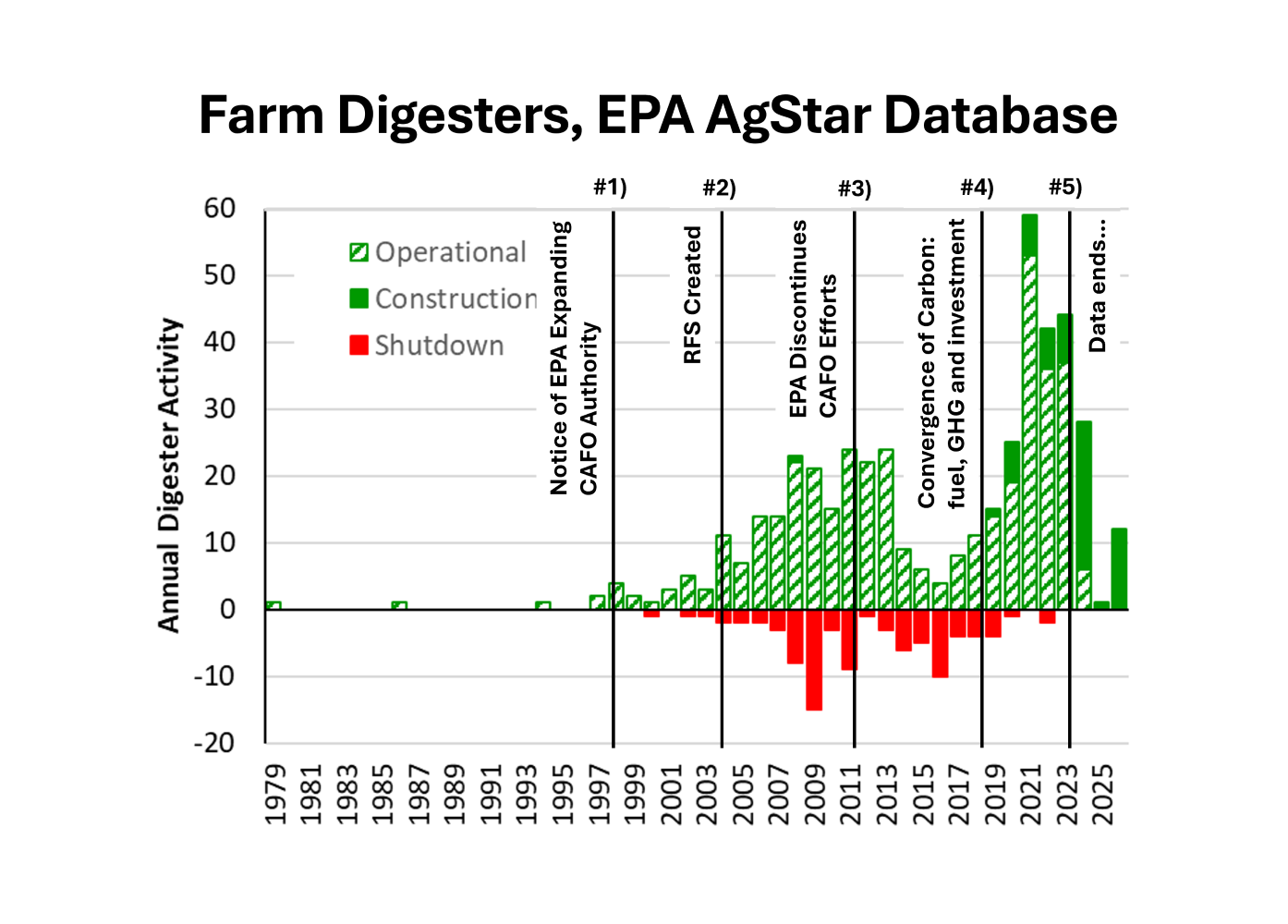

Revenue-generating renewable methane is real and a growing industry. My encounter with MAAS Energy Works at Simpson University in Redding, California earlier this month, was a homecoming for Biomass Rules. The importance of this topic was reenforced with the American Biogas Council, Business of Biogas Conference held in St. Louis, Missouri this week. A graphic of the growth of the US farm digester industry was in order.

Anaerobic lagoons on farms sprung out of the compliance period of the Clean Water Act (1972). In the 1970s and 1980s, US farms invested in cost effective anaerobic manure lagoon technologies. They were simple and relied on natural biological systems to stabilize potential carbon-based pollutants into methane gas. During the 1990s and 2000s the agricultural community, along with everyone else, realized that creating and emitting methane gas into the atmosphere was not really what we wanted to be doing. Oops.

Agricultural engineers are brilliant. And as we began implementing the Clean Water Act, anaerobic digesters that transformed waste carbohydrates into biogas fuel began to appear. Once the awareness of the negative impacts of emitting methane became clearer, more closed anaerobic digesters began appearing on livestock farms.

#1) In 1999, the US EPA announced it was going to begin regulating farm manure emissions. On August 25, 1999, the EPA posted in the Federal Register, their, ‘Notice of Availability: Draft Guidance Manual and Example NPDES Permit for Concentrated Animal Feeding Operations.’ While the state environmental agencies and local farms all continued to work at protecting the waters of the US, the growth of farm size, particularly livestock operations was unforeseen. In the late 1990s, multiple national manure spills began making news headlines and prompting more restrictive regulatory oversight. This also prompted a few more anaerobic digesters to appear on livestock farms.

#2) In 2005, legislation creating the Renewable Fuels Standards (RFS) was created.

While the Concentrated Animal Feeding Operation (CAFO) manure rules were driving from the federal level at EPA down to the states, the renewable fuels legislation was driving by the states up to the federal level. On September 11, 2001, the US was attacked by individuals from oil producing nations. This provoked a mission to become less dependent on foreign oil. At about the same time, multiple service station underground fuel tanks had leaked of fuel into the ground water. A larger problem was the fuel additive, MTBE, used to control Clean Air Act fuel emissions, causing grave health concerns in those fuel spills. By 2005, seventeen states had outlawed the use of MTBE in fuel and substituted ethanol to control the Clean Air Act emission concerns. Ethanol as a fuel additive maintained the air quality, while improving water quality.

When the RFS were created there was not much direct influence on the growth of anaerobic digesters on US farms. However, there were now at least three pressure points impacting farm regulation of manure. First, the clean water aspect. Second, the emission of methane directly into the environment was no longer acceptable. And third, there was funding and passion for energy independence from foreign energy suppliers.

Digester expansion during the ’00s was driven by the ongoing efforts of EPA to impose stricter regulations on manure production and use, and a difficult – but possible – quest for energy production from manure digesters. Digesters do fail though. Often, they fail from farms going out of business. But they are biological technologies and must be managed as such. Shocks to the system will disrupt their complex biology. Once this happens, restarting the desired ecosystem is not as simple as flipping a switch or replacing a part.

#3) In 2012, the EPA announced it was foregoing new regulatory efforts on manure production and use. Rules produced in 2003 and 2008 resulted in lawsuits against EPA that prevented the rules from becoming law. The threat of legal action and stricter regulations put the livestock industry into action mode. But by 2012, the livestock feeding industry had realized they had not included bypass phosphorus in their feed formulations. This is phosphorus that is unavailable to the animals for nutrition. This new awareness created with the attention of regulatory action, allowed them to begin feed formulation on total phosphorus. This reduced the amount of phosphorus leaving livestock facilities in manure and did not diminish livestock growth. It was a win-win. Regulation was averted, and the industry corrected a costly oversight. The manure spills reflected a failure of government solutions. The feed formulation oversight indicated failure of the markets. But new information provided the motivation to find a solution.

With the regulatory pressure relieved and the energy conversion technologies feasible, but difficult, the mid-2010s saw reduced digester construction and continued digester failure (both farm closure and digester operations).

#4) By 2018 the technology to clean biogas into predominately methane, or renewable natural gas (RNG) became more affordable and efficient. At the same time several federal infrastructure expansion funding bills were passed in 2021 and 2022. Pressure to take action on climate concerns made RNG a viable solution for achieving clean energy and bringing organic waste back into the economy. Farm digester growth has been expanding. It trails off in 2024 in this dataset, but that is more a function of the EPA not publishing more recent data.

#5) This dataset was published in September of 2024 and likely was several month behind at that point. There were 11 farm digester projects under construction without a projected start date and there were also 11 farm digesters that had shut down without a reported date.

This EPA AgStar data is excellent and a service to society that it is maintained. There is much more data included than what is presented in this chart. This chart does not show predominant species providing manure to the system. It also does not show digester size, which has been increasing over time.

This data does show that there have been phases of farm digester expansion that have been driven by different factors: technology innovation, waste and environmental remediation, and renewable energy opportunities. It took 20 years of commercial experimentation, from 2000 to 2020, to get to a level of technology and industry stability to launch farm digester expansion.

Comments

Cultivating Fuel on Farms and the Growth of the US Farm Digester Industry — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>