Byproduct Value in Closed and Open Production Systems

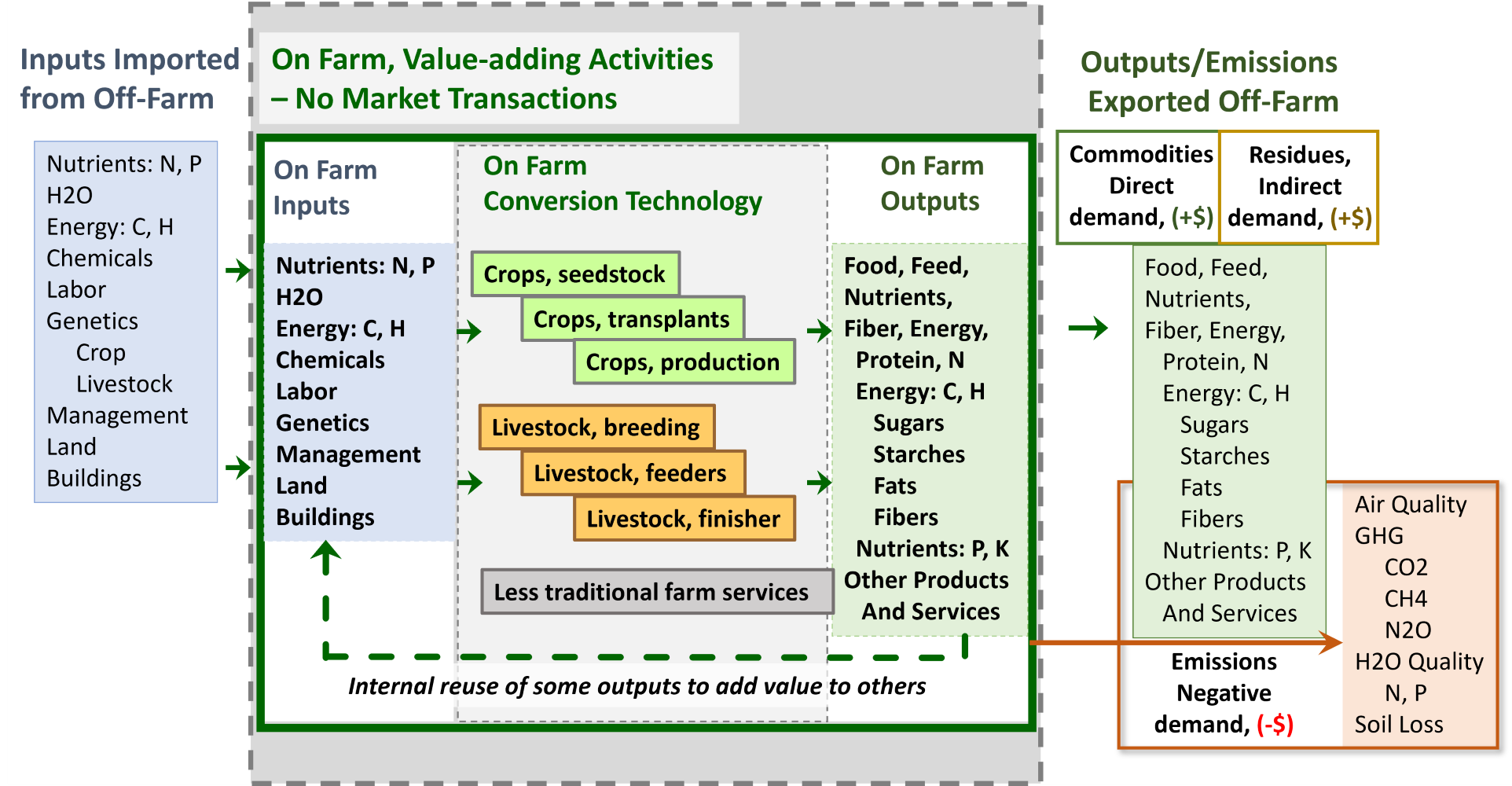

What in the farm-data mess is this? …It is a map to providing pathways for turning wastes into revenues.

This is Part 4 in stepping through the impact of technology on making the world better economically and ecologically. Recall:

- Outputs are dependent on the inputs, or, y = f(x). Technology is defined by inputs transformed into outputs.

- Byproducts, whether they have monetary value or not, are part of the production system (Technology and Hog Production)

- By knowing available materials, byproducts, and available technologies, revenue generation is within reach!

Human nature seeks the simplest explanation for any question, and then calls it finished. Production systems, including farms are nothing simple or straight-forward. They are complex and all different.

Closed and Open Systems: There are multiple functions happening within the conceptual container of a closed and an open system. For the economists, open systems are separable. Today, a farm may produce a single product, like feeding young pigs (weaned pigs) to market weight (finishing hogs). Fifty years ago, a hog farm likely grew the corn, mixed it into feed rations, bred the female pigs (sows), farrowed the new pigs, weaned the pigs, and finished the pigs into market hogs.

Feeding corn to hogs on the same farm is the simplest form of vertical integration. Hog inputs (corn) were grown and fed to hogs, the next link in the chain, even though the corn didn’t leave the property. Alone, this is not important. It becomes more important in making sense of the current industry structure of vertically integrated livestock production. It has been going on functionally for a long time.

The current hog production system is open and separable because each enterprise stands on its own. The same farm may still produce corn and hogs, but the corn may be mixed into feed at the integrated hog owner’s feed mill, before it is fed to the hogs on the same farm.

Back in the 1960’s, corn and other feed ingredients were purchased and mixed on the hog farm, so the flow was more closed than open. Hog producers likely bought, or imported, corn from other farms to feed the capacity of hogs on their farm. The shift to more separable components in the livestock industries has been facilitated with new technologies and market structures. The closed and open ideas are still influential.

Non-market Benefits of Closed Systems (no market data): A more current closed farming system is the cow-calf grazing systems of the Midwest. Places like southern Missouri, cannot grow high-yielding grains, but do well growing forages. The University of Missouri pioneered development of intensive grazing technologies. In the 1990’s, MU showed that when managed intentionally, more beef could be produced on fewer acres, producing all but about a month of winter hay and only adding nitrogen to pastures each year. The forages were optimized for,

- The highest nutritional quality

- Animal stocking rate was balanced between number of animals and daily available forage

- Mechanical harvesting of winter feed was minimized or eliminated

- Fertilizer, leftover feed, was spread by the grazing animals as they moved from paddock to paddock

- Forage nutrients were only removed in the elements that left the farm as beef weight gained.

Pricing of Closed Farm Outputs Occur upon Export off the Farm: On-farm reuse only has a quantity. There are no market transaction prices. Manure nutrient reuse only has an offset value of the cost of imported commercial fertilizer nutrients purchased, unless confined animal manure is processed into a value-added 1) energy and 2) nutrient external markets. Similarly, lagoon effluent leakage into natural waterways, or methane (CH4, natural gas) leakage into the atmosphere. Then the off-farm exported value is a liability and has a negative value, or cost.

This information is not new, only a reformatting of traditional farm economics. This framework allows externalities, or leakages, to be internalized BEFORE they become external.

Like all management tools, closed systems are no better than open systems. Local conditions will prevail in identifying decisions to be made. Mapping of on-site and off-site, inputs, transformations and outputs, promote systems thinking in evaluating solutions. The best solution may still be an efficient enterprise-based, open market system. Systems analytical tools are valuable tools in the policy and business management toolbox.

Comments

Byproduct Value in Closed and Open Production Systems — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>