Morphing Waste to Revenue – Breaking Free of Old Views

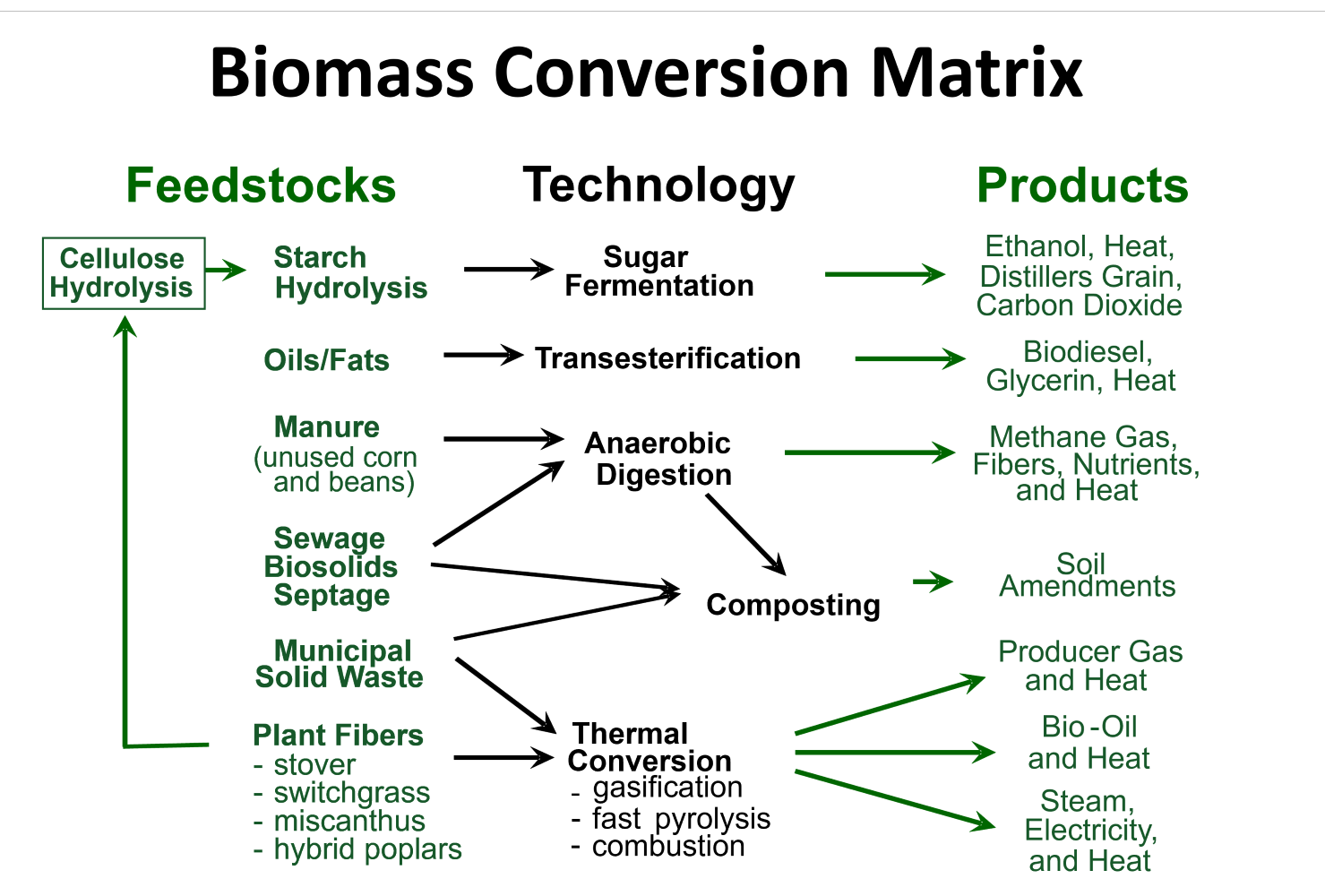

Once again, strolling back to the future, this matrix of biomass products was created 20 years ago. It still relevant and ties together the preceding themes nicely on a different level.

- Outputs are dependent on the inputs, or, y = f(x). Technology is defined by inputs transformed into outputs.

- Byproducts, whether they have monetary value or not, are part of the production system (Technology and Hog Production)

- By knowing available materials, byproducts, and available technologies, revenue generation is within reach!

Feedstocks: Remember this is a business enterprise development map from 20 years ago. The Feedstocks in this input -> technology -> output model are byproducts from production systems. When undermanaged, they pile up and become liabilities (disposal costs). When transformed into a product or service with value, the same surplus wastes become revenue streams.

Technologies, y=f(x): The technologies are self-explanatory. Basically, biological technologies work well for liquid materials. Thermal technologies work well for dry materials. Plus, it is possible to mix and match. Biogas produced from anaerobic digestion can be combined with biogas from gasification. This is an oversimplification, but it works for illustration.

The difficult part is that biogases reflect the material/feedstock from which they originate and the technology that transforms them. The best chance of combining fuels is in having consistent feedstocks into the same technologies. Test prospective technologies with intended fuels.

One of the secondary markets while consulting in the ’00s with Biomass Rules, was troubleshooting why some technologies didn’t work as forecasted. It nearly always went back to simply using manufacturer tabled values to plan, rather than running independent tests with intended feedstocks. Tests do cost more but spending a few thousand dollars to validate and adjust the plan with relevant data is money ahead of spending millions of dollars that did not work.

Products (and Services): Biofuels leap off this list. But mixed in with the fuels are other products that serve other markets, soil amendments, livestock feed, industrial gases. Services may not have a direct monetary value. An odor-reducing digester project may reduce the cost of hauling liquid manure miles away from the farm because the offensive manure odors become less offensive. That is a cost offset of hauling costs that are reduced.

Evaluating multiple markets at once is not the traditional separable market – enterprise budget way. This means the system of farm production equations gets more complicated.

- Y(hogs) = f(feed, genetics, energy, etc.)

- Y(energy) = f(organic feedstocks, technology, heat, etc.)

- Y(nutrients) = f(spent feedstocks, technology, storage, offset values, etc.)

Or the sum of all the enterprise outputs, Y(system) = Y(hogs) + Y(energy) + Y(nutrients) – Y(offsets).

Simply looking only at the most valuable product in an enterprise analysis only provides part of the story. There is one more piece to this lesson on technology and systems. Outputs reused on a production facility have no marketing costs. Evaluating on site use has a different cost structure than selling or purchasing products and inputs from off site. This final piece is likely the most overwhelming cacophony of production yet. More soon.

Comments

Morphing Waste to Revenue – Breaking Free of Old Views — No Comments

HTML tags allowed in your comment: <a href="" title=""> <abbr title=""> <acronym title=""> <b> <blockquote cite=""> <cite> <code> <del datetime=""> <em> <i> <q cite=""> <s> <strike> <strong>